Item | Quartz sand proppant | ||||

Product Code | Type I (0.850-0.425mm) | Type II (0.600-0.300mm) | Type III (0.425-0.212mm) | Type IV | |

Roundness/Sphericity | ≥0.6 | ≥0.6 | ≥0.6 | ≥0.6 | |

Acid Solubility (%) | ≤5 | ≤5 | ≤7 | ≤7 | |

Turbidity (NTU) | ≤100 | ≤100 | ≤100 | ≤100 | |

Bulk Density (g/cm³) | ≤1.55 | ≤1.55 | ≤1.55 | ≤1.55 | |

Apparent Density (g/cm³) | ≤2.6 | ≤2.6 | ≤2.6 | ≤2.6 | |

Conductivity | ≥10 | ≥10 | ≥10 | ≥10 | |

Broken Rate(%) | 28MPa | ≤314 | -- | -- | -- |

35MPa | -- | ≤10 | ≤7 | ≤7 | |

Quality Assurance Period | 12 Months | 12 Months | 12 Months | 12 Months | |

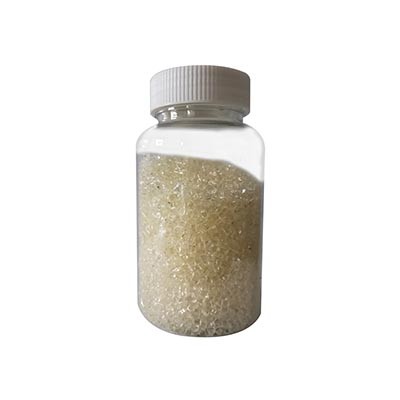

Quartz sand proppant is a kind of filler used in oil extraction process. Its main function is to maintain the stability of the oil well. During the construction process, by adding quartz sand proppant, it can fill the cracks in the well wall, prevent the collapse of the well wall, and ensure the normal production and output of the oil field. The quartz sand proppant produced by our company has the characteristics of pressure resistance, high strength, low density, good sphericity, high smoothness and strong flow conductivity.

Storage and transportation conditions

1. The quartz sand proppant should be stored in a cool and ventilated place, and should be kept away from heat and fire sources.

2.The quartz sand proppant should be protected from impact during transportation. It is strictly forbidden to mix with food for transportation.